Insulated storage container for IBC and mother-daughter tank (Proviron)

The customer

Proviron (Oostende) Offers high-quality chemical products used for a wide range of applications and a broad spectrum of chemical processes, including polymerization, multi-step synthesis, and formulation.

Purpose

Pilot installation to safely pump chemical liquid delivered via IBC to the consumer in the factory.

Problem-solution

After discussing the P&ID (provided by the client), our draftsman started designing all components in the storage container Through several rounds of feedback, the 3D model was continually optimized for ergonomics.

Finding space for all components in the container, while ensuring everything remains accessible, was an additional challenge. Moreover, we modified the mother-daughter tank so that the IBC never needs to be pushed too deep into the container, eliminating the need for long forks on the forklift.

the mother-daughter tank,pump cabinet, partition wall en piping (stainless steel) were manufactured in our own CGK workshop.

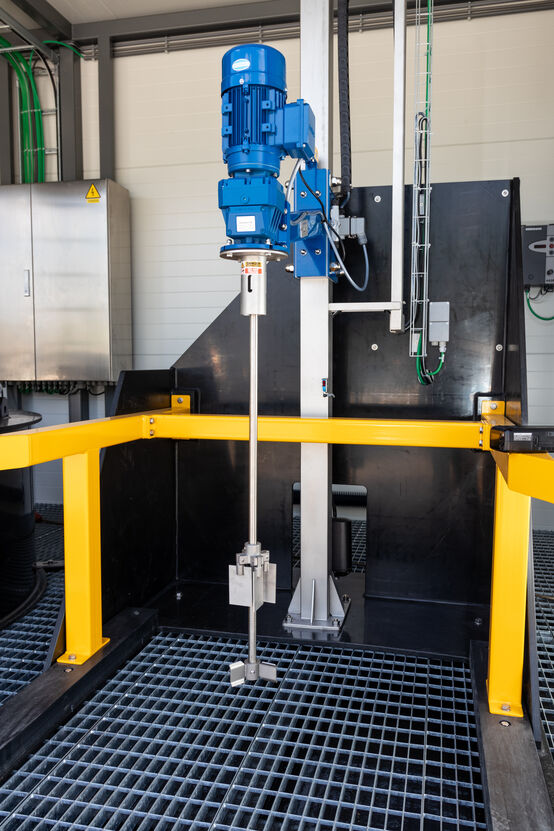

- The agitator is used to mix the liquid in the IBC before it is pumped (so that any sediment settles is mixed again).

- Next, the IBC is emptied using the special mother-daughter system. The tank is equipped with a digital radar to monitor the amount of liquid. Continuous pumping is possible (without downtime due to IBC replacement).

- Because the liquid in the IBC becomes more viscous (thicker) as the temperature drops, the mother-daughter tank is insulated and equipped with an internal heating resistor. Heating jackets are also available to place around the IBC. The storage container itself is equipped with three heating elements.

- Given that it concerns a hazardous liquid, leak detection is integrated into the floor grates to notify the control room in case of a leak. Furthermore, the drip tray extends across the entire surface of the container.

- The container includes a separate 'room' (made of plastic) where the pump box is isolated, aiming to minimize the risk of splashing and leaks to human and environmental safety.

- The three major advantages of putting such installations in a container?

- no modifications to existing building required

- all chemical processes take place safely outside the production environment (in accordance with VLAREM)

- easy to move (mobile)