Process installations

Frequently, in addition to a tank, pump, or pipework, a comprehensive approach is required that encompasses everything from engineering to the commissioning of the entire installation.

The turnkey process installations can be about mixing or heating liquids for various applications.It is possible to build installations in batch as well as continuous.

Total approach to process installations

CGK Group guarantees the smooth running of the project thanks to a turnkey team consisting of a sales and project engineer, a technical designer, a service technician together with the necessary welders, pipefitters and installers, who are always available.

Engineering of process installations

The first step is the translation from a summary process description. We convert the process required for production into a P&ID.

We think about how the process can be translated into reality in order to achieve proper installation operation:

- Research into which sensors, dosing or transfer pumps and valves are needed. The selection of these is done in consultation with the customer in order to maximally match the standards already applicable in the company.

- In terms of safety and the environment, we think of the big picture, such as providing an eye wash and emergency shower or a soaking facility.

- Necessary insulation in thermal processes.Material selection based on the

During the engineering phase, we draw out the entire installation in our 3D package. This ensures good accessibility of the various components right from the start.

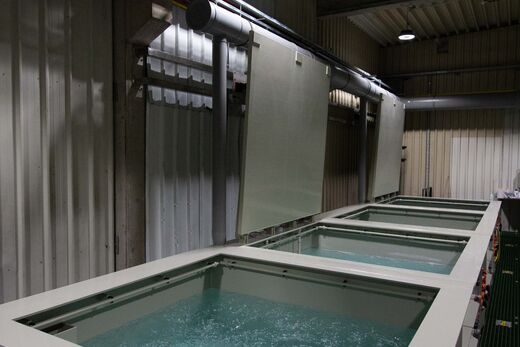

Construction and testing of process plants

After design approval, we start building the installation. The installation is built and tested to the maximum in our production hall, both in terms of hardware (leak tightness and pressure tests) and software (IO tests ...).

It is possible to carry out a FAT in our production hall so that we can then build the installation in your company. After the SAT, the installation is ready for use.

During design, we put maximum effort into skid construction. This allows us to minimise assembly time on site

Commissioning of process installations

We submit a complete technical file with manual, drawings, CE certificate, Vlarem certificate, spare parts list ... Peace of mind guaranteed. Our engineering thinks of everything.

Need a process installation that requires a comprehensive approach?

Get more information or request a no-obligation quote.