Engineering

CGK Group actively thinks along with you. The result is a sustainable solution for your specific challenge.

In-house engineering team

- To guide you during the study phase, we have a strong in-house team of engineers, draughtsmen and project leaders. No rough estimates, but well-founded analyses that ensure you get a realistic view of the project's impact, duration and budget.

- You can also count on always having one personal point of contact.

- With the preliminary draft that flows from our research, you will have a solid and valuable basis to practically work out the project. This can be done with CGK or another partner of your choice.

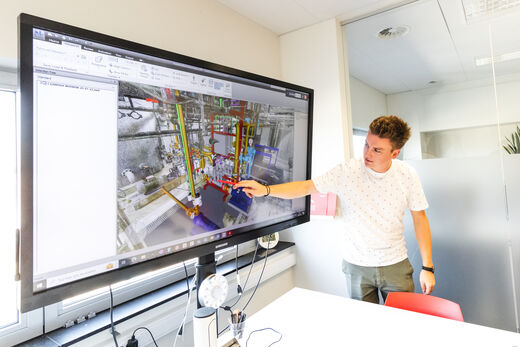

3D scans

A virtual image of your company (zone)

As manual measurement takes a long time, is often complex and not always possible in a crowded factory, we opt for efficient 3D scanning technology. 3D scans of a site, factory or production hall allow us to produce pipework in advance in our workshop (prefab). This reduces our presence on site and causes minimal disruption to production.

- High precision

- Large volumes in a short time span

- All measurements are combined into one

- No need for shelving or production stoppage.

- Time savings over traditional methods

Based on these detailed digital images, we can accurately design installations at your desired location. Pipes, pipe bridges, structures such as platforms, whether in GRP, steel, or stainless steel, and more! We can even design tanks, pump units, containers, or skids and then integrate them into your site.

Accurate budget calculation

Thanks to our advanced 3D analysis, we take the guesswork out of your budget planning. With accuracy and precision, we calculate in advance which elements are crucial for your installation.

Our 3D scans enable us to identify the elements needed for your project, allowing us to determine the budget perfectly in advance. No more surprises or unexpected costs - we offer you a clear understanding of what to expect.

FEM analyses

Kosten en tijd besparen door simulaties

Thanks to our advanced FEM analyses, your project is sustainable and you can be sure it will pay off for a long time.

- By performing simulations of your installation or systems, we can estimate important issues in advance, such as how big the load of certain structures may be, the plate thickness, the right profile ...

- We also take the environment into account. Chemical vapours or sea air, for example, require a different choice of materials than a packaging hall. In this way, we avoid unforeseen problems in the future.

Based on FEM analysis, we design more efficiently and thus always cost-effectively.

Process analysis (P&ID)

- Thanks to our extensive knowledge and experience in process engineering, we design completely new process installations and also make modifications to existing installations.

- During our study, we take time to understand your company's current processes. Whether it is dosing, mixing chemicals or other aspects, we thoroughly analyse which pumps are most suitable and how to design the process in the most optimal way.

- We integreren jouw processen zo goed mogelijk binnen je productieproces en houden rekening met je wensen, gebruikmakend van slimme procesontwerpen en de nieuwste technologieën.

CGK is an expert in Process Engineering: producing more efficiently, safely, sustainably, flexibly and/or cheaply by optimising your production environment.

Present us with your challenge ...

... and we figure out what the best solution is.