Replacement of More Than 70 Dephosphatation Tanks (Aquafin)

The customer

Aquafin treats wastewater until it is clean enough to return to nature, contributing to an environment in harmony with water. The Flemish water treatment company also promotes sustainable rainwater management to help prevent dry soils and mitigate the impact of heavy rainfall.

Purpose

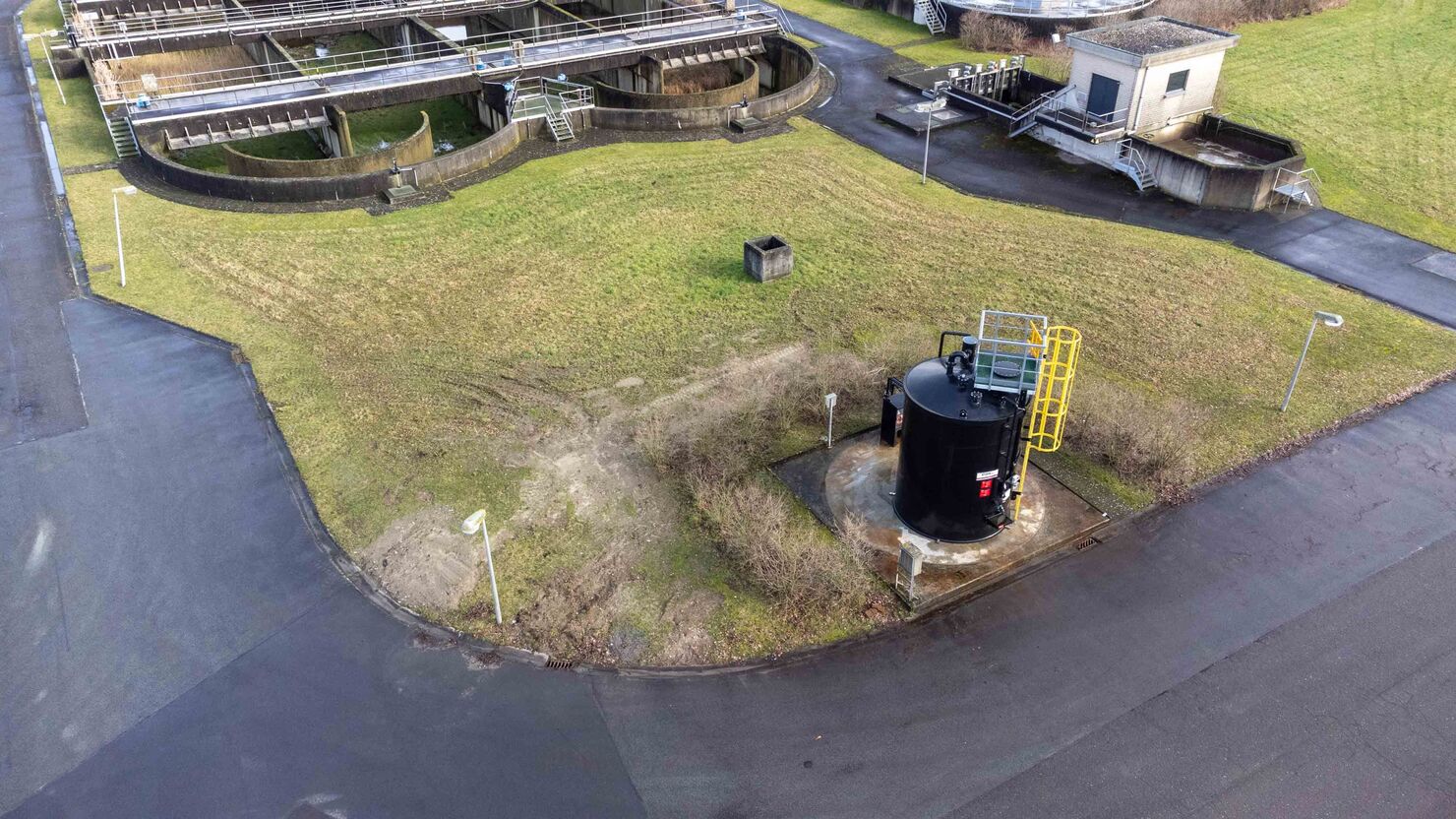

Design, Construction, Transport, Installation, and Commissioning of More Than 70 Double-Walled Iron Chloride Tanks with Dosing Pump Cabinets

CGK is responsible for all aspects of the project, including the removal of the old tanks and dosing systems. We maximize cradle-to-cradle recycling of the discarded PE material, ensuring a sustainable approach to the project.

Problem-solution

As the lifespan of these dephosphatation tanks reaches its end after 20 years, and Aquafin must comply with VLAREM regulations for hazardous product storage, we are responsible for replacing a large batch of existing iron chloride tanks.

Iron(III) chloride is used to remove phosphorus from water, a crucial step in wastewater treatment. Phosphate in the water binds to the iron chloride, forming flocs that settle at the bottom, allowing for easy removal.

Following Aquafin’s guidelines, the new tanks have undergone a significant upgrade. We are replacing the outdated tanks with:

- BENOR-certified double-walled tanks (15 m³ and 25 m³), each equipped with:

✔ A fiberglass-reinforced (GRP) platform and caged ladder for safe access

✔ A pump cabinet for iron chloride dosing

✔ Double-walled plastic piping to prevent corrosion (as iron chloride is mildly corrosive)

At our Gullegem workshop, the tanks and pump cabinets are fully assembled before installation. Our technicians then dismantle the old tanks on-site and install the new ones.

- Complete switchover within just 1 week per unit

- Seamless transition with minimal disruption to operations

CGK Group acts as the all-in-one partner for:

- Dismantling & removal of old tanks

- Recycling & cradle-to-cradle reuse of PE materials

- Design & engineering of the new system

- Manufacturing & on-site installation

With this turnkey approach, we ensure compliance, efficiency, and sustainability in Aquafin’s dephosphatation process.