Design and installation of filling cabinets, storage tanks, and pump cabinets (Belgosuc)

The customer

Belgosuc produces semi-finished products from selected natural sugars, ranging from bulk to small packaging. The company targets the artisanal and industrial food industries with its own product range and customized solutions.

Purpose

Due to increasing production, the demand for chemicals grew. As a result, it became more economical and efficient to have their chemicals delivered in bulk rather than in IBCs.

Problem-solution

CGK Group managed the storage and distribution of HCl and NaOH effectively.

By replacing IBCs with storage tanks, the distribution process is now fully automated. This ensures that operators no longer need to manually dispense chemicals at a central dispensing point, making the process both more efficient and safer.

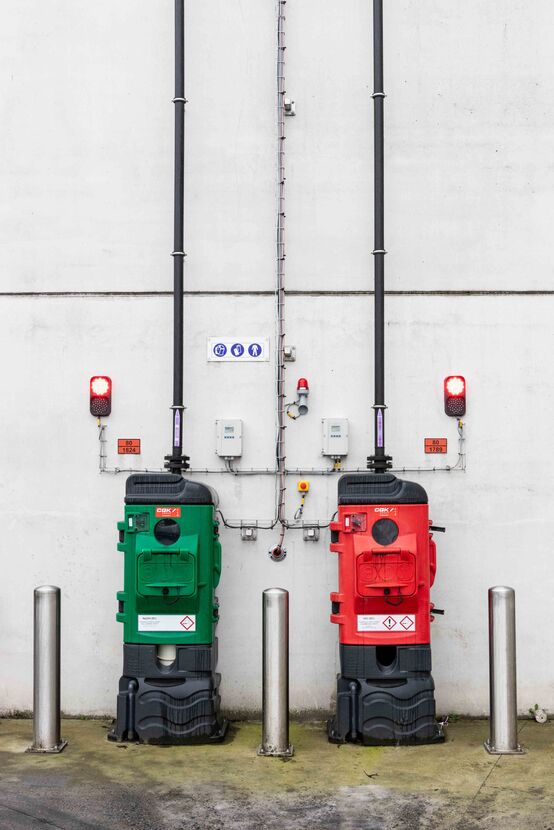

1. Filling Cabinets at the Loading Area

- Color-Coded Cabinets: Two filling cabinets (red for HCl and green for NaOH) are each equipped with specific truck couplings and a containment tray for potential leaks.

- Level Monitoring: Connected to radar measurement, the liquid levels can be easily monitored.

- Safety Design: An opening for the filling hose allows the cabinet door to remain closed during filling, enhancing safety.

- Automatic Shutoff: A controlled valve in the cabinet automatically closes when the tank’s overfill protection system sends a signal.

2. Storage Tanks

- Double-Walled Tanks: The filling line extends through the building to two double-walled storage tanks of 10 m³ each (HCl & NaOH).

- Accessibility: Both tanks feature a fiberglass-reinforced plastic (FRP) platform for easy access.

- HCl Tank Gas Scrubber: A gas scrubber is connected to the HCl tank to absorb fumes released during filling. The scrubber is insulated and heat-traced to prevent freezing in winter. If the outdoor temperature drops below 5°C, the liquid is heated.

- NaOH Tank Insulation: The NaOH tank and pipelines are also insulated and heat-traced to ensure continuous operation in freezing conditions. Temperatures below 15°C can cause NaOH crystallization.

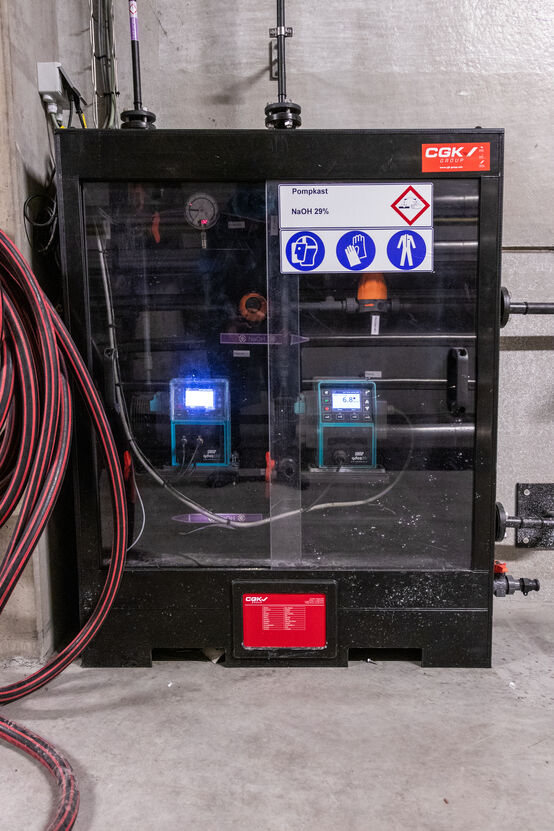

3. Pump Cabinets

- Durable Construction: Fully enclosed pump cabinets are made of plastic resistant to HCl and NaOH.

- Accessibility: The piping and pumps are accessible via transparent sliding doors.

- Leak Protection: The base includes a built-in containment tray with leak detection.

- Safety Features: The piping system is equipped with all necessary safety measures.

End-to-End Project Management

CGK Group handled the entire project, from design and production to transport and installation, ensuring a seamless and safe solution tailored to the customer's needs.