Tank installation for more efficient and safer wastewater management (Engie Rodenhuize)

The customer

Engie is an international energy company specializing in the production and distribution of electricity, natural gas, and sustainable energy solutions.

Purpose

The old tank installation in Ghent no longer met current safety and environmental standards. Together with Engie, we designed and implemented a solution that operates more efficiently and offers a higher level of safety.

Problem-solution

In the past, Engie used large storage tanks for their acid and lye (in this case, sodium hydroxide and hydrochloric acid). Due to changes in their operations and a reduction in consumption, less storage capacity was needed. As a result, they decided to replace the large tanks with smaller, more manageable ones.

Context

For wastewater discharge, Engie must comply with specific discharge conditions, including constant monitoring of the water's pH level. To stay within the required limits, the pH is continuously measured. If the pH deviates from the permissible range, it can be adjusted using acid or lye. The new installation plays a crucial role in this process, allowing Engie to intervene quickly and precisely.

The Installation

In collaboration with one of our colleagues, a modern tank installation was designed in consultation with Engie. The outdated setup with drip trays was replaced by:

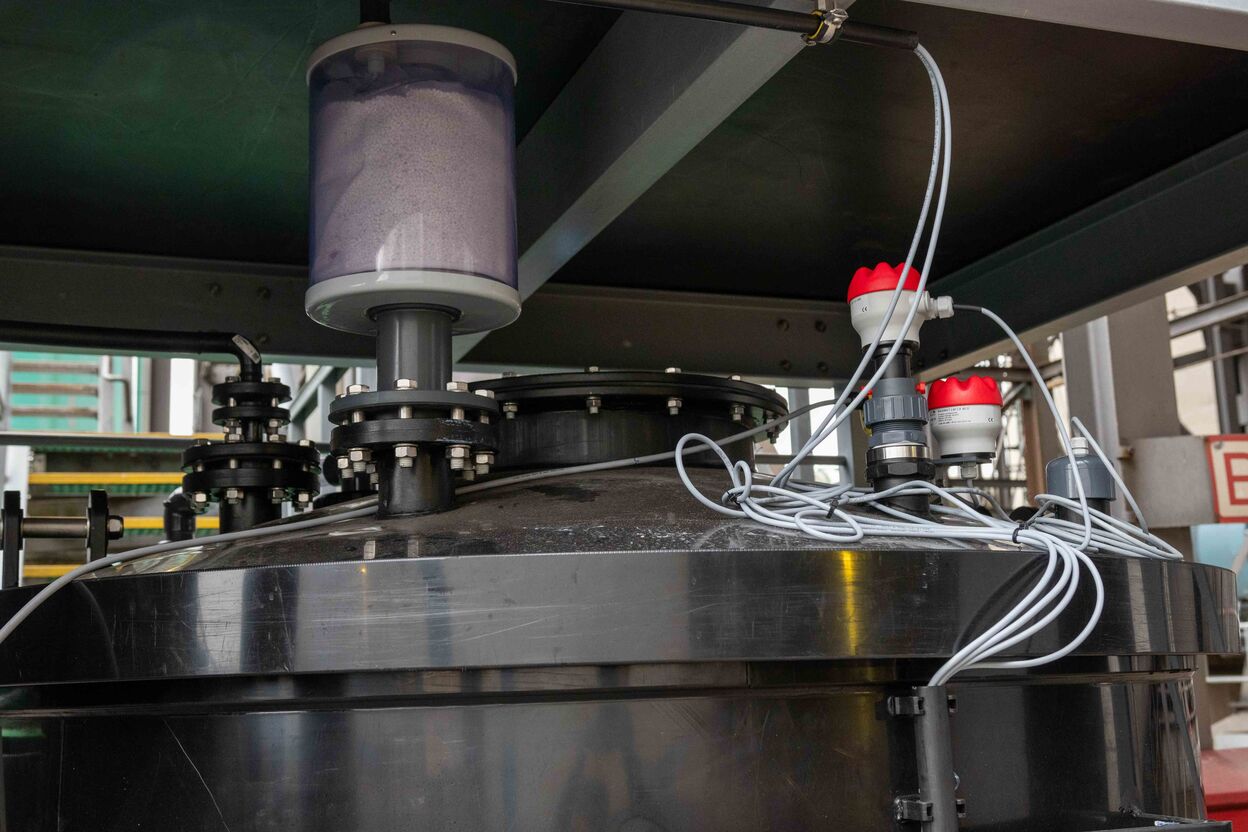

- Two double-walled storage tanks, each with a capacity of 2.5 m³, equipped with leak detection and overfill protection.

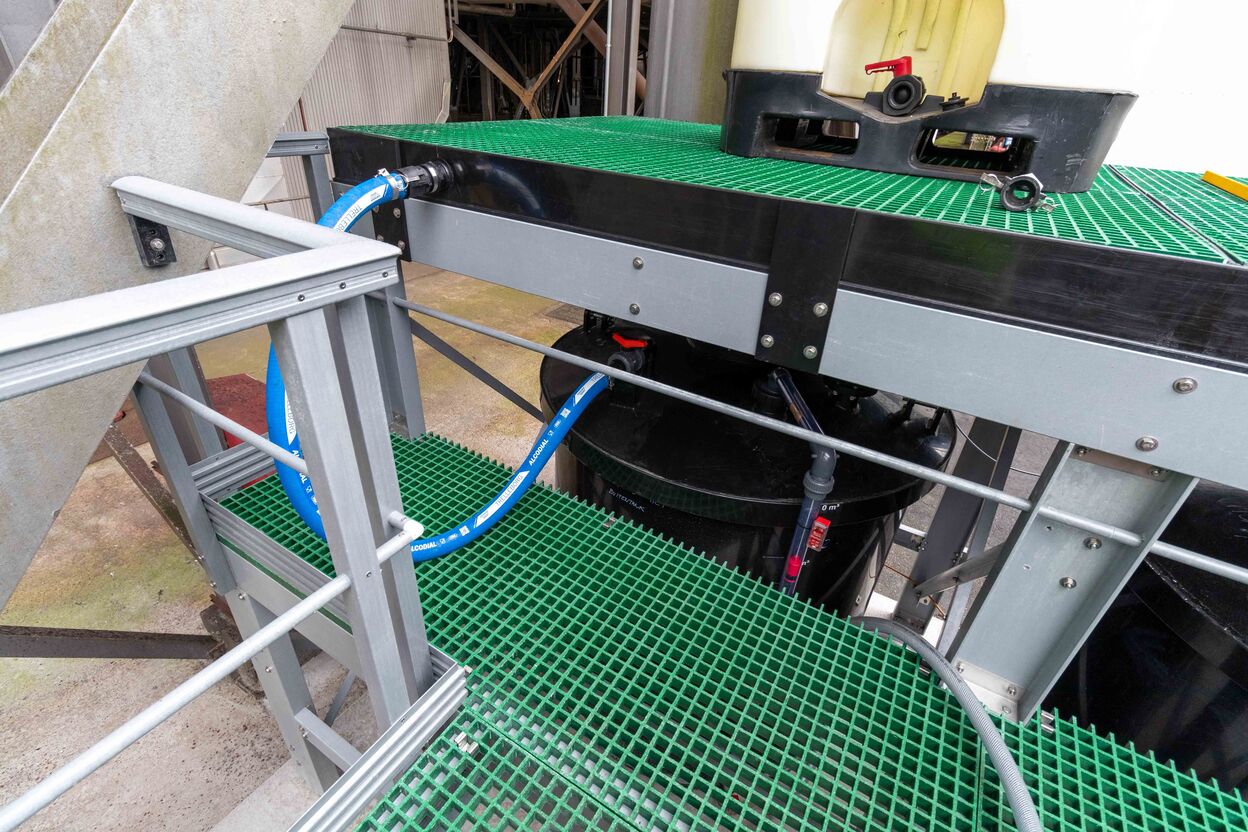

- A new fiberglass-reinforced plastic (FRP) platform with a containment tray.

Insulated sodium hydroxide tank and pipes to prevent crystallization.

Operation

In plaats van gebruik te maken van complexe pompen, werkt het systeem via een natuurlijke hevelwerking om de chemicaliën te transporteren. Het aanvoeren van nieuwe voorraad gebeurt met behulp van een heftruck, waarmee IBC-containers veilig kunnen worden aangesloten op de tanks. Dit proces is veiliger dankzij het verhoogde platform en de lekbakken waarin de IBC’s geplaatst zijn. De lekbak is verdeeld in twee compartimenten, zodat eventuele lekkages van zuur en loog gescheiden blijven en niet kunnen mengen.

Instead of relying on complex pumps, the system uses a natural siphoning mechanism to transport chemicals. New supplies are delivered using a forklift, which safely connects IBC containers to the tanks. Safety is enhanced by the elevated platform and containment trays where the IBCs are placed. The containment tray is divided into two compartments to keep potential acid and lye leaks separated, preventing mixing.

Advantages of the New Setup

- Safety and Environmental Protection: The modernization improves site safety and reduces environmental impact through smaller storage volumes.

- Simplified Operation: The design eliminates the need for complex pump systems, simplifying operation and reducing the risk of errors.

- Easy Refilling: The compact storage and natural siphoning system enable timely refilling of tanks without complicated procedures.

- Ergonomic Design: The intermediate platform facilitates a convenient and safe connection of IBCs.

- Compliance with VLAREM Standards: The installation meets strict Flemish environmental regulations (VLAREM), ensuring adherence to discharge conditions.