Installation of storage tanks and dosing (Bio Base)

The customer

Bio Base Europe Pilot Plant is active in process development, scale-up, and production of innovative bio-based products and processes.

Purpose

The company in Ghent needed, on one hand, an upgrade of the existing chemical dosing system and a larger storage capacity.

On the other hand, they wanted to expand for the use of new chemicals.

Problem-solution

CGK Group was responsible for the engineering, production, delivery, and installation of 4 double-walled storage tanks.

Specifically, this involved an outdoor setup with storage tanks featuring flat bottoms and conical roofs:

- 1 storage tank (35 m³) with pump chamber for ammonia (NH4OH):

- A passive gas scrubber is connected to the tank. To replace the water in a safe and ergonomic manner, the gas scrubber was mounted at a comfortable height.

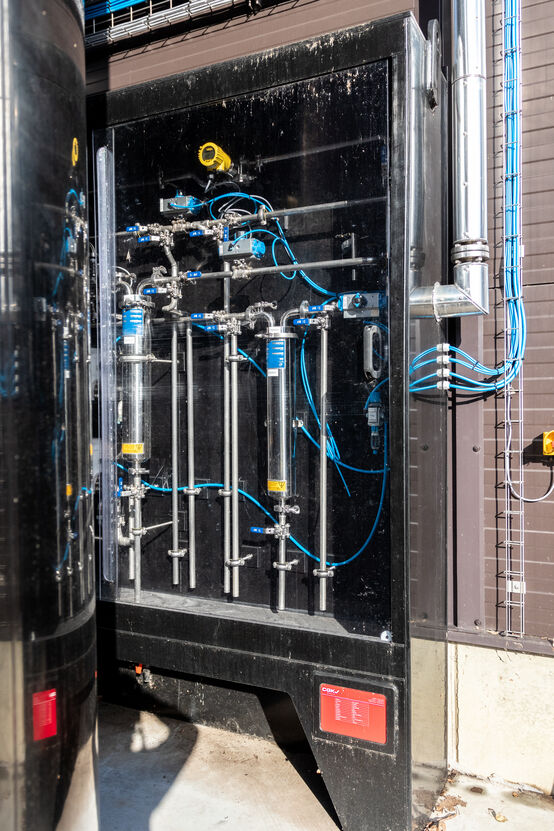

- An additional filter panel is connected to this ammonia tank.

- 3 storage tanks (each 12 m³) with corresponding pump chambers for sodium hydroxide (NaOH), phosphoric acid (H3PO4), and sulfuric acid (H2SO4):

- The NaOH tank is insulated and equipped with tracing between the jackets.

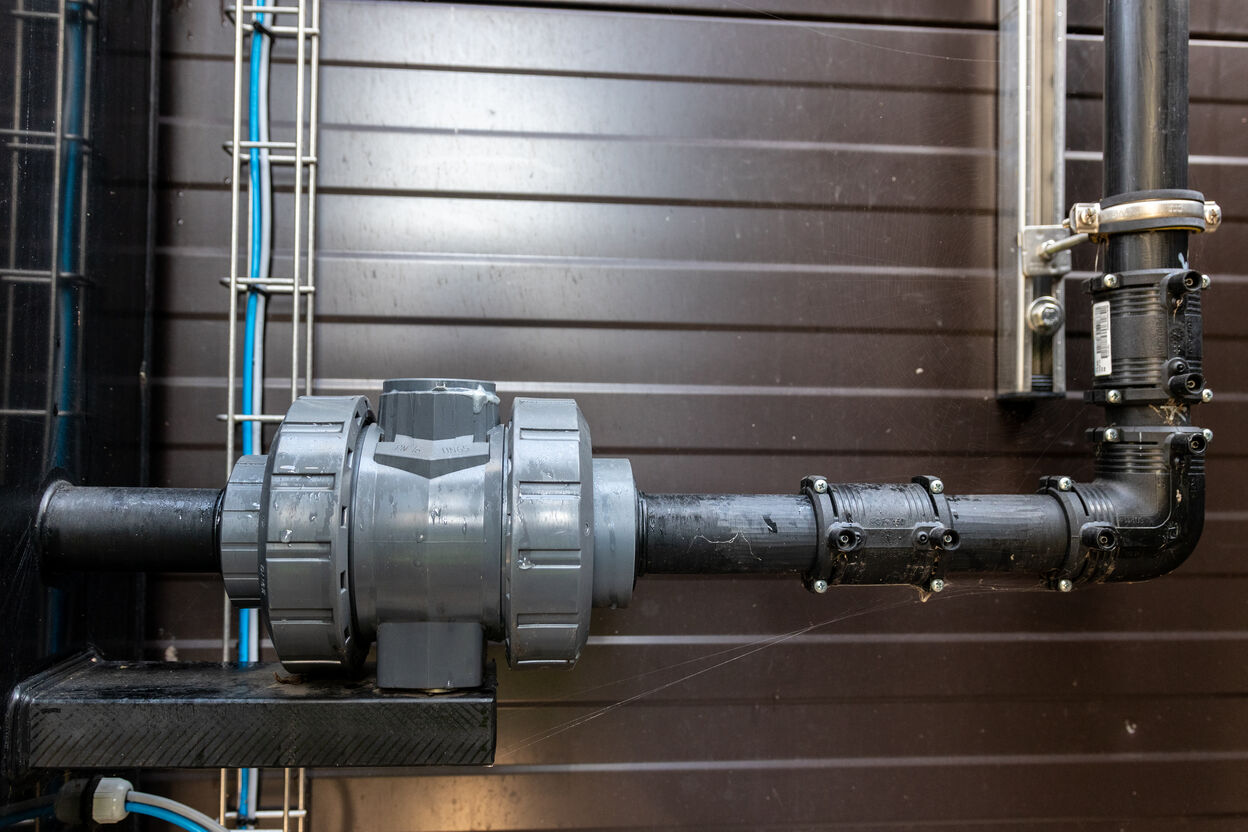

- All materials used and the piping were adapted to the properties of the liquids. We worked with both stainless steel (RVS) and plastic.

- Both the large and smaller tanks are equipped with a controlled filling valve, overfill protection, signal box, leak detection, level float, etc.

Our engineering department was responsible for:

- Creating a P&ID (Process and Instrumentation Diagram),

- Creating 3D & 2D drawings,

- Ensuring compliance with VLAREM II regulations and European standards,

- Conducting and reporting pressure tests,

- Preparing the lifting plan to properly manage the installation of such large tanks,

- Preparing the installation user manual,

- Preparing part of the CE certificate,

- Conducting the commissioning inspection of the storage tanks.

The team that realised this project

Sales Engineer Tim

Technical Designer Glenn

Project Engineer Bjorn

Constructor Stijn

Constructeur Bart

Insulator Rakesh

Insulator Guillaume

Steel pipefitter Koen

Steel pipefitter Patrick

Steel pipefitter Sebastien

Steel pipefitter Enno

Plastic welder David

Plastic welder Guy

Plastic welder Sander

Plastic welder Marc

Plastic welder Renaat

Plastic welder Dylan

Plastic welder Karel

Plastic welder Micha

Plastic welder Filip

Plastic welder Philippe

Plastic welder Ronny

Plastic welder Karel

Plastic welder André

Plastic welder Jelle