Firewater collection (Janssen Pharmaceutica)

The customer

Janssen Pharmaceutica is active in research and development (R&D), manufacturing and the launch of new drugs.

Purpose

Loyal customer Janssen Pharmaceutica contacted us to install liquid barriers in a new facility where chemicals are processed and stored.

Problem-solution

Fluid barriers are designed to make an entire site or certain parts (e.g. doorway, gate or passageway) fluid-tight.

1) If a fire breaks out in the area where Janssen Pharmaceutica's chemicals are stored, the sprinklers are triggered. The extinguishing water contaminated with chemicals can thus damage employees and the environment (by seeping into the soil). By installing liquid barriers, this is avoided.

2) Any chemical leaks are also contained by liquid barriers.

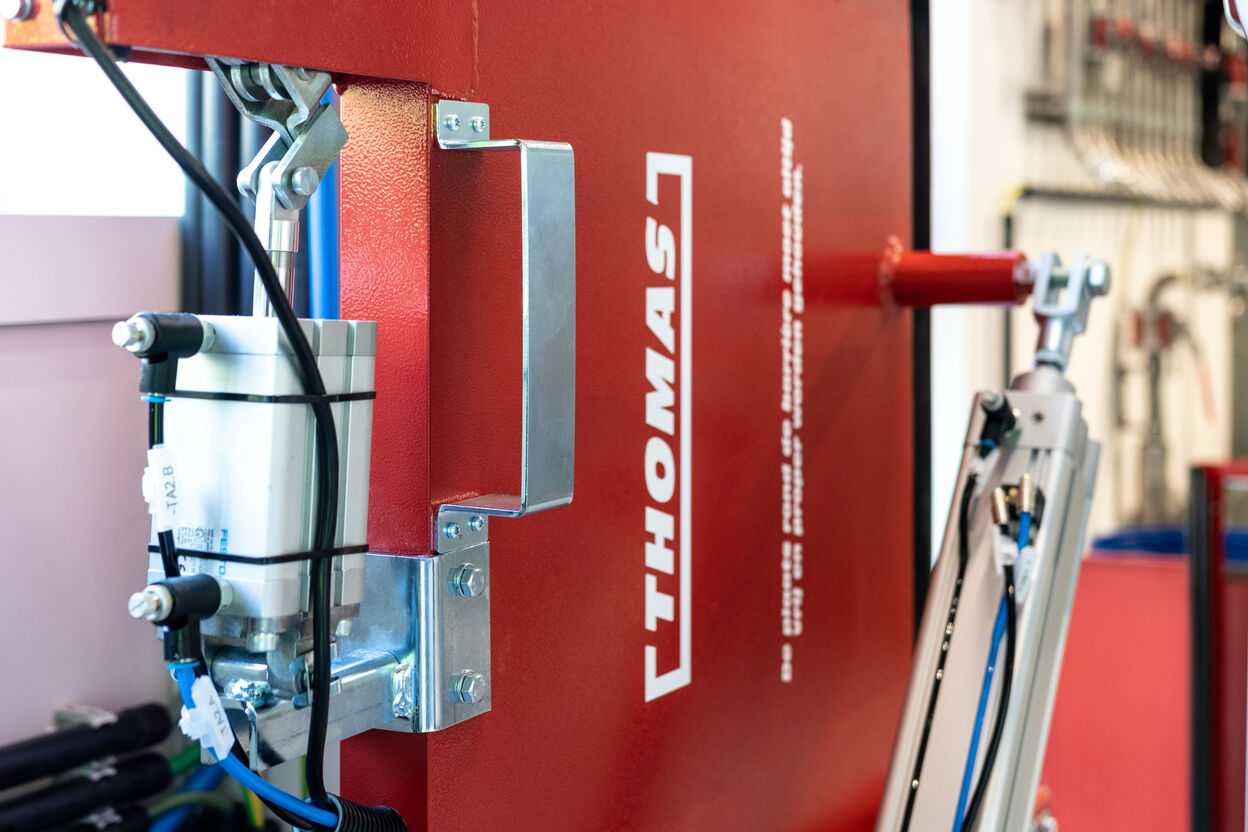

CGK installed fully automatic liquid barriers at the doorways and emergency exits of the facility:

- As the barriers were placed in an explosion-prone environment, the version is fully ATEX certified.

- The barriers are equipped with a booster to increase the force of compressed air to automatically close and open the heavy barriers.

- The barriers are equipped with a feedback contact. As an additional check, the system sends back a signal when all barriers are closed.

- Outside, we installed a guillotine liquid barrier that closes by means of pneumatic tensioners. To protect against rain, the outdoor installation is fully galvanised and fitted with protective covers.

- We work exclusively with the best quality liquid barriers from German manufacturer Thomas.