Vertical agitator

Ideal solutions for mixing tanks up to 1500 m³ with one agitator

Our agitators are equipped to mix liquids in tanks up to 1500 m³. Maximum efforts are made to work with standard solutions, but customised engineering is of course always possible.

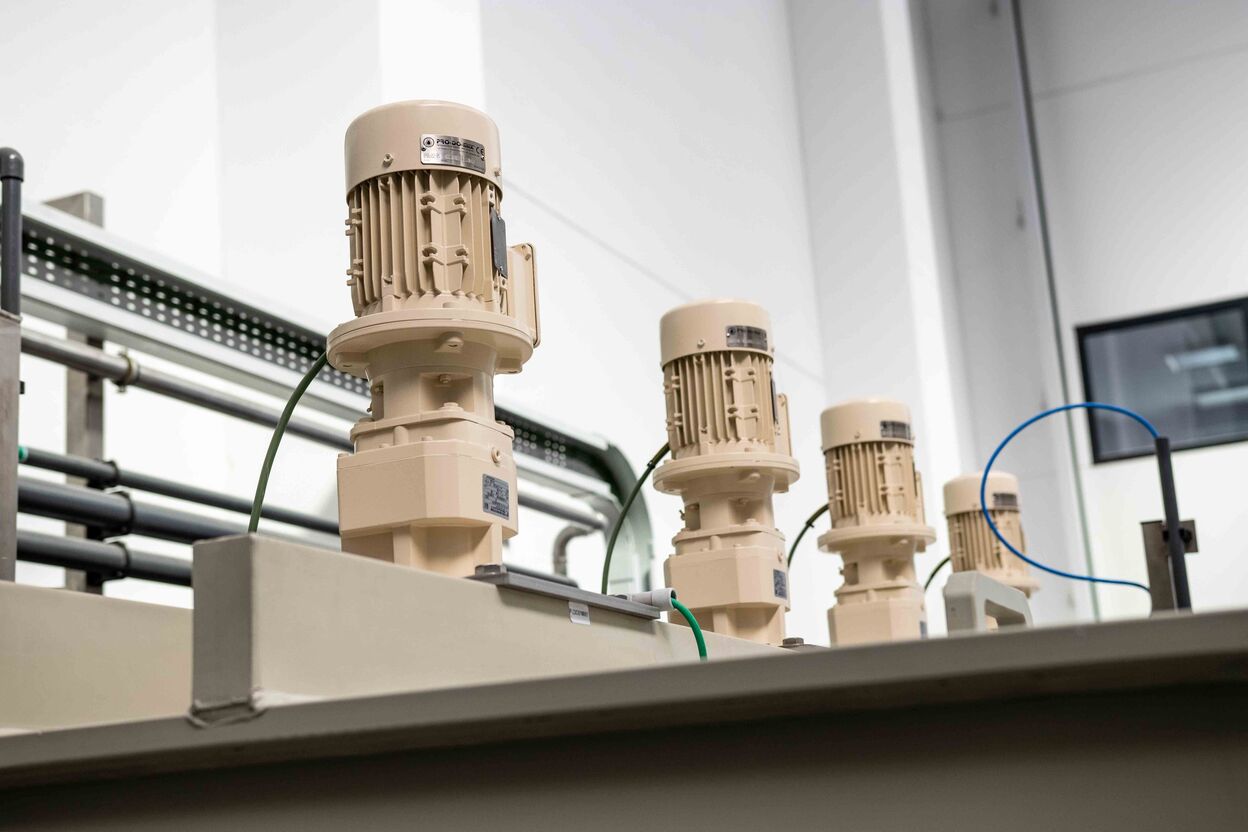

CE-marked quality

All CGK agitators are CE marked, with the logo clearly visible on each machine. We provide a technical data sheet of each CE-certified agitator.

Safe and reliable in hazardous environments

Our agitators can be produced according to Directive 2014/34/EU-ATEX, suitable for installation in potentially explosive environments.

Request a price

Applications

The applications are wide-ranging:

- suspend solid parts in a liquid

- heat transfer

- make liquid more homogeneous

- …

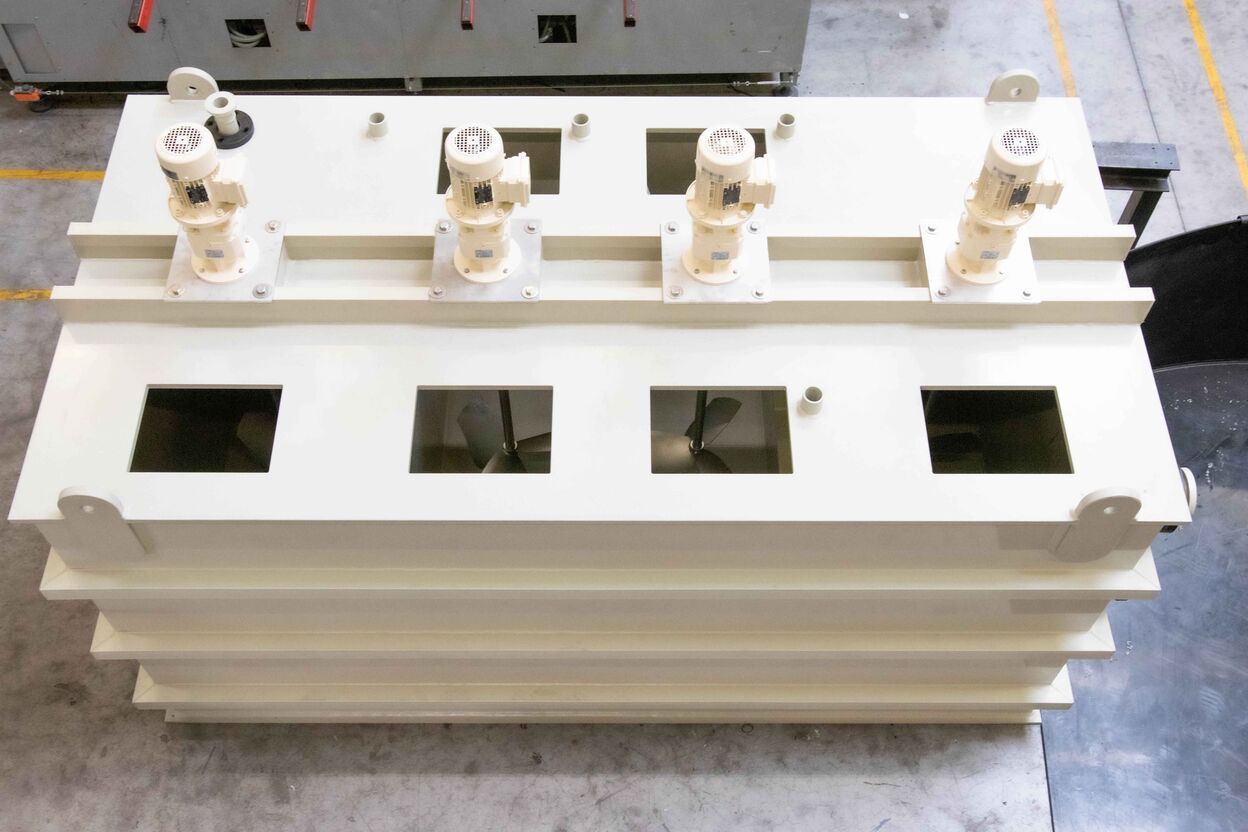

4 types of vertical agitators

Vertical agitators up to 180 m³

Vertical agitators up to 180 m³ are mainly used in wastewater treatment and a wide range of industrial applications. The speed of the agitator is adjustable from slow, fast to very fast. Various materials are possible, ranging from steel and stainless steel to a coating with PP, ECTFE, ebonite, etc. Shaft lengths go up to 3,500 mm and an impeller up to 1,500 mm.

Vertical agitators from 180 m³ to 1500 m³

Agitators from 180 m³ to 1500 m³ serve mainly for large volumes of liquid that need to keep moving (e.g. in water treatment plants). Here, we are talking shaft lengths of up to 6 metres, impellors of up to 4 metres and a power output of up to 45 kW.

Vertical agitators for slurry or sludge

We also offer agitators specifically for slurry or sludge. These are applicable in production plants such as cement or ceramics or mining.

Customised vertical agitators

For specific applications where our standard solutions cannot take us any further, we make custom-made agitators.

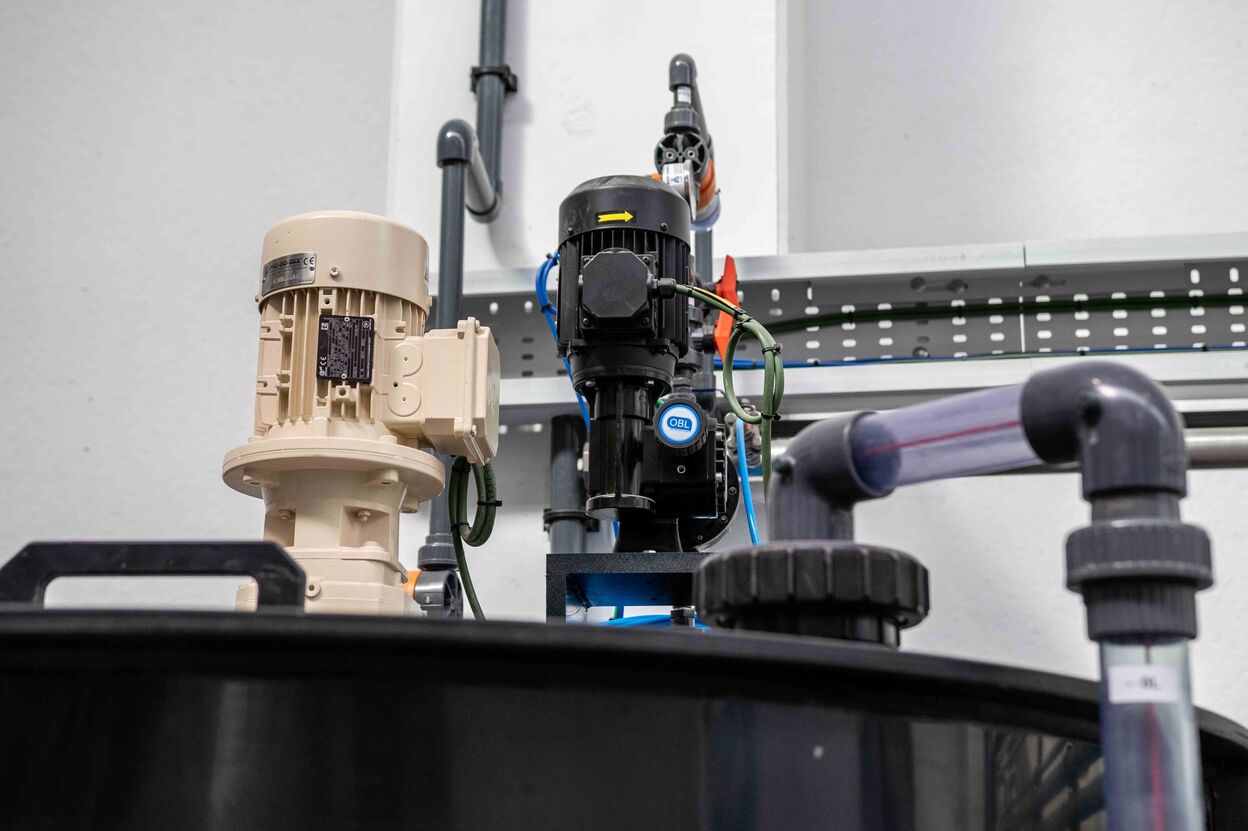

Customised agitators

We can adapt motor power, impeller shape and machine speed to your specific needs. This results in 100% customised solutions. Our agitators are suitable for any type of liquid, even at high densities of up to 2.5 kg/m³. This prevents sedimentation, improves heat exchange and promotes chemical reactions.

Technical capabilities

- Power: 0.09 kW - 45 kW

- Drive: motor with reduction gearbox, direct control, pneumatic or hydraulic

- Assembly: IEC motor flange, rectangular mounting plate, welded bearing, DN flange, ASME flange

- Bearing: with or without additional bearing

- Shaft seal: radial seal (lip seal), packing seal, labyrinth seal, single or double mechanical seal

- Shaft: solid material, seamless tube, flanged separate parts

- Impellers: process-dependent

- Bearings: bottom bearing if necessary

- Material: steel, SS304, SS316, lining

- Finish: according to food suitability 1935/2004/EC

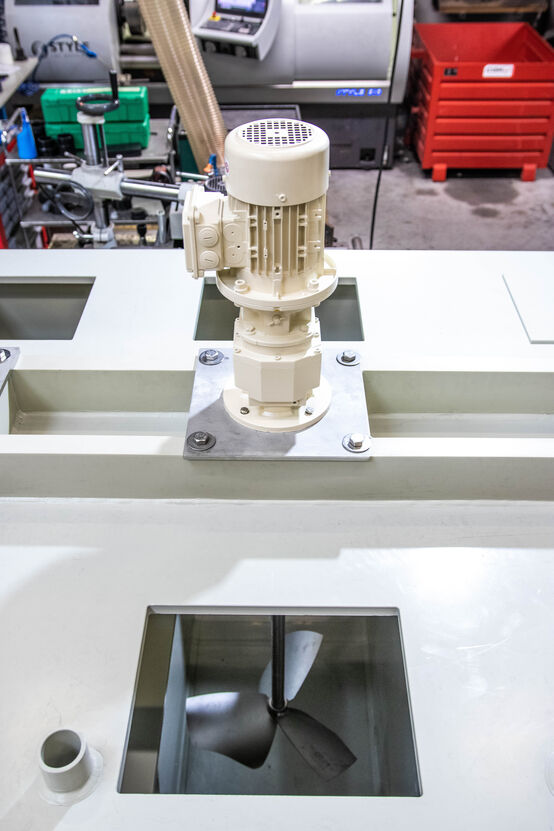

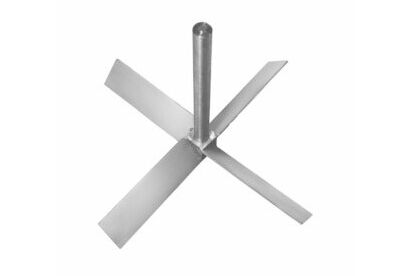

Impellers

The heart of the agitator is the impeller. The shape of the impeller is fully customisable. We have a very wide range of options to mix your solution correctly.

Request a price for your agitator now

Curious about the possibilities and prices of our agitators? Simply submit your price request below. Our team is ready to help you!