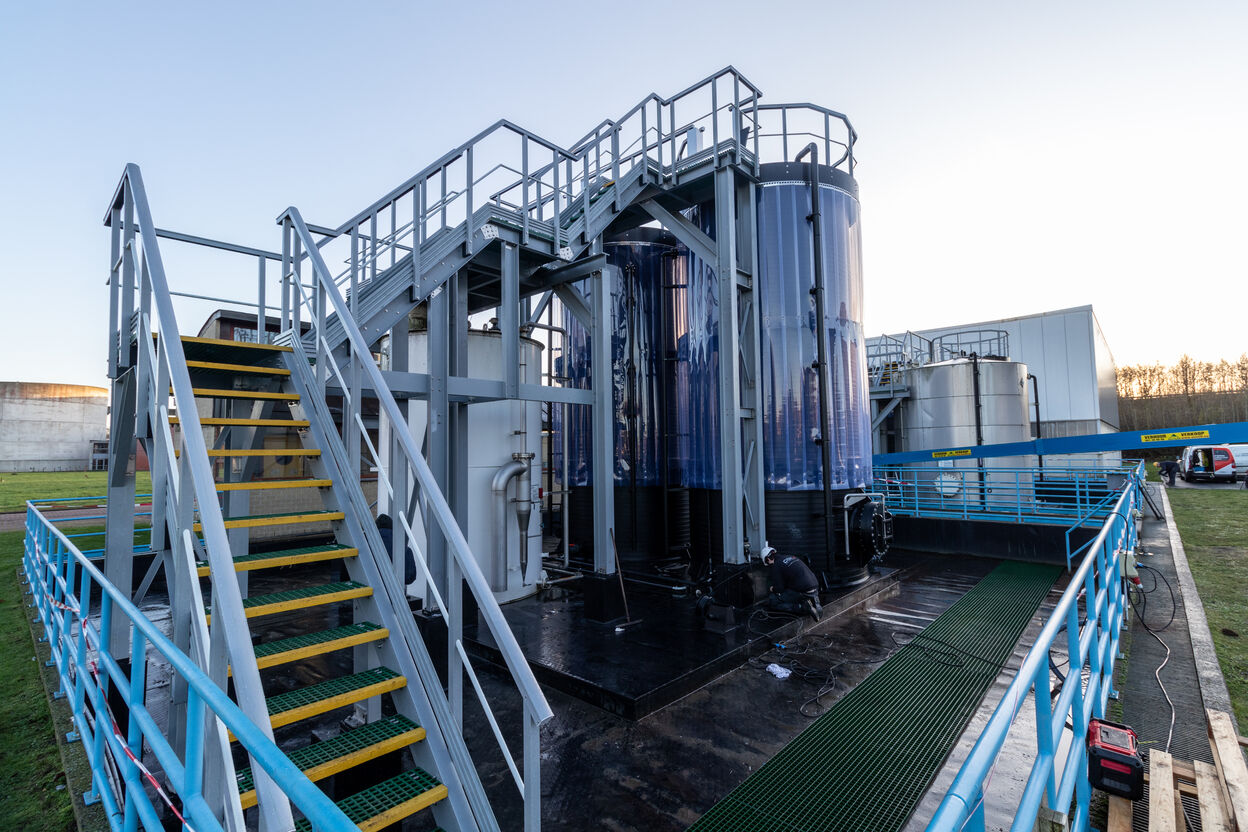

Replacing storage tanks & placing GRP structures at WPC De Gavers (Water Group)

The customer

In De Gavers water production centre (Harelbeke-Stasegem). De Watergroep makes drinking water based on surface water from the Bossuit-Kortrijk canal. water from the Shelde is pumped and treated there directly and without a buffer from the canal.

Purpose

At the De Gavers water production centre, the existing tanks for iron trichloride and bleach came to the end of their lifespan. They were thus in need of replacement.

Problem-solution

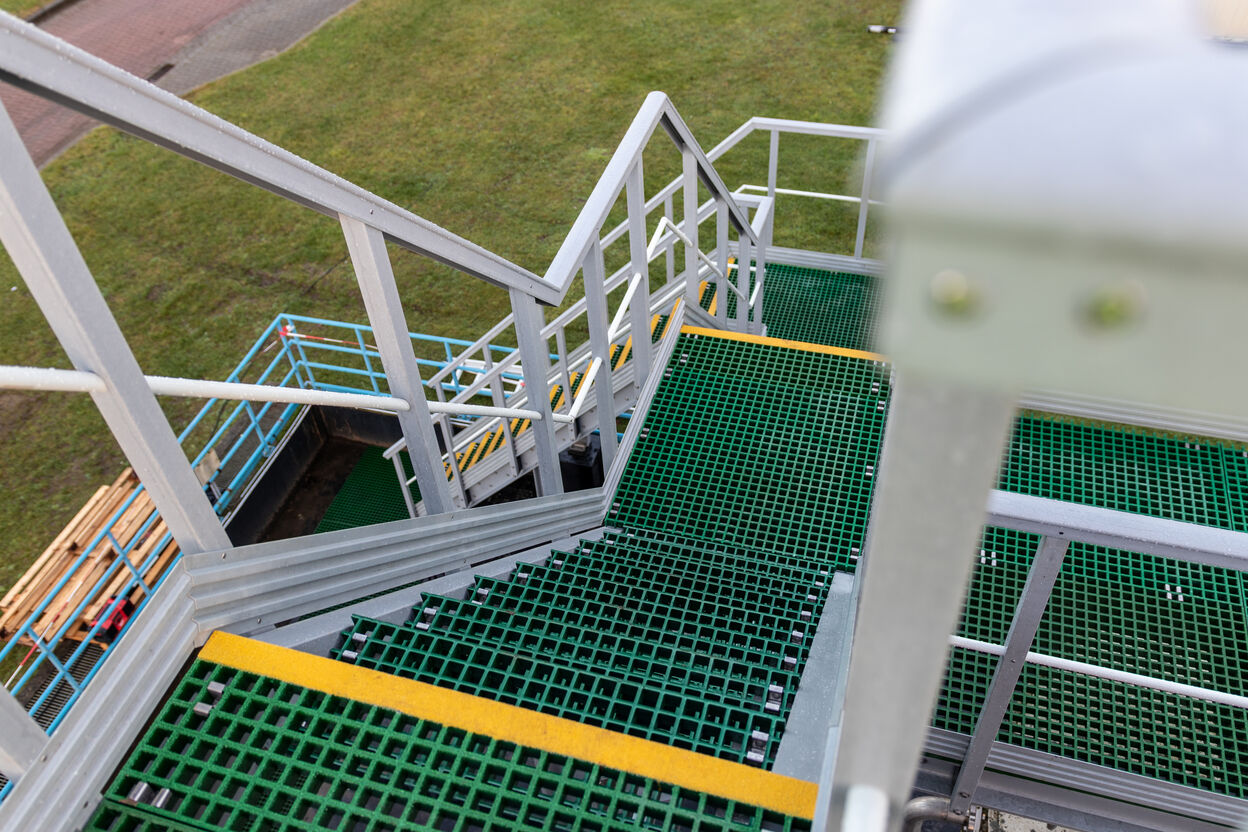

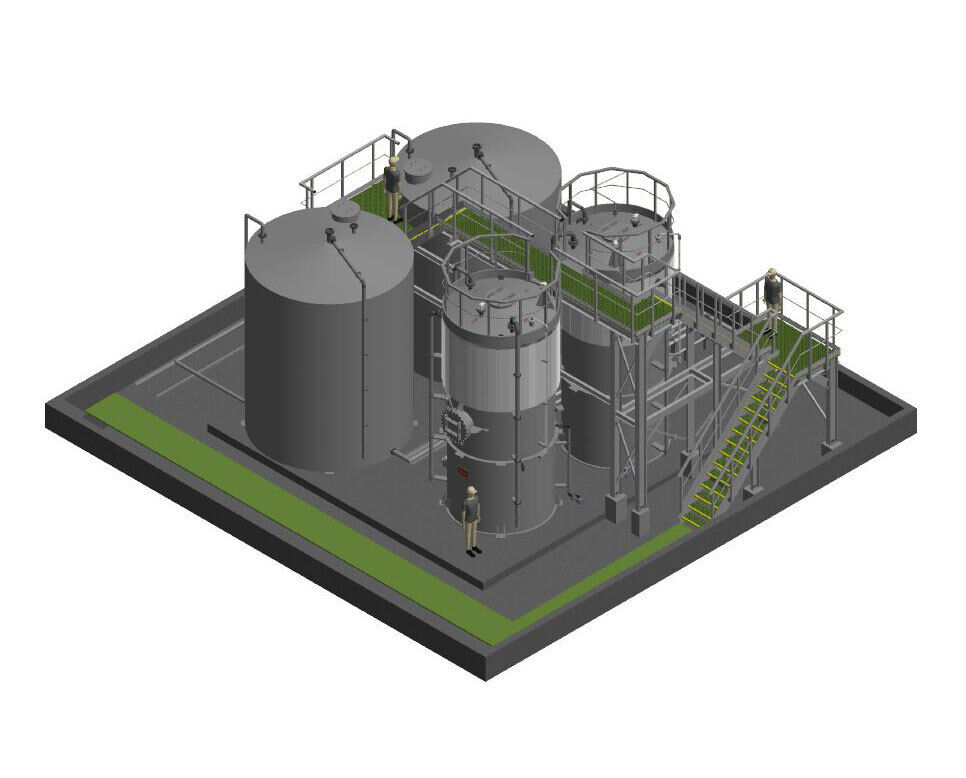

- CGK installed 4 single-walled tanks in PE wrap-around tubing in a concrete bund lined with PE: 2 to replace the iron chloride tanks and 2 to replace the bleach tanks.

- By replacing the tanks 1 by 1, we ensured that the water purification system at the centre could continue to operate. While one tank was in use, the other was replaced.

- The bleach tanks were placed on a pedestal 2 meters high to ensure that air bubbles enter the tank and never into the pump.

Each tank is equipped with splash guards on the sides to contain leaks within the bund wall.

- There is a manhole in the tanks with a special hinge system (=davit system) that makes it easy to open and close the heavy hatch.