Dosing Installation for NaOH & H₂O₂ (Schrurs)

The customer

Schrurs of Ypres is a flake dyer and textile finisher.

Purpose

Working more safely and efficiently with H202 and NaOH.

Problem-solution

- Previously, chemicals were transported to processing sites via small drums. CGK Group installed double-walled storage tanks with overfill protection and leak detection, in accordance with VLAREM II. 1 of 30 m³ for the H202 and 1 of 15 m³ for the NaOH. As a result, chemicals are automatically dosed to all work stations. Safer work, less consumption and fewer working hours.

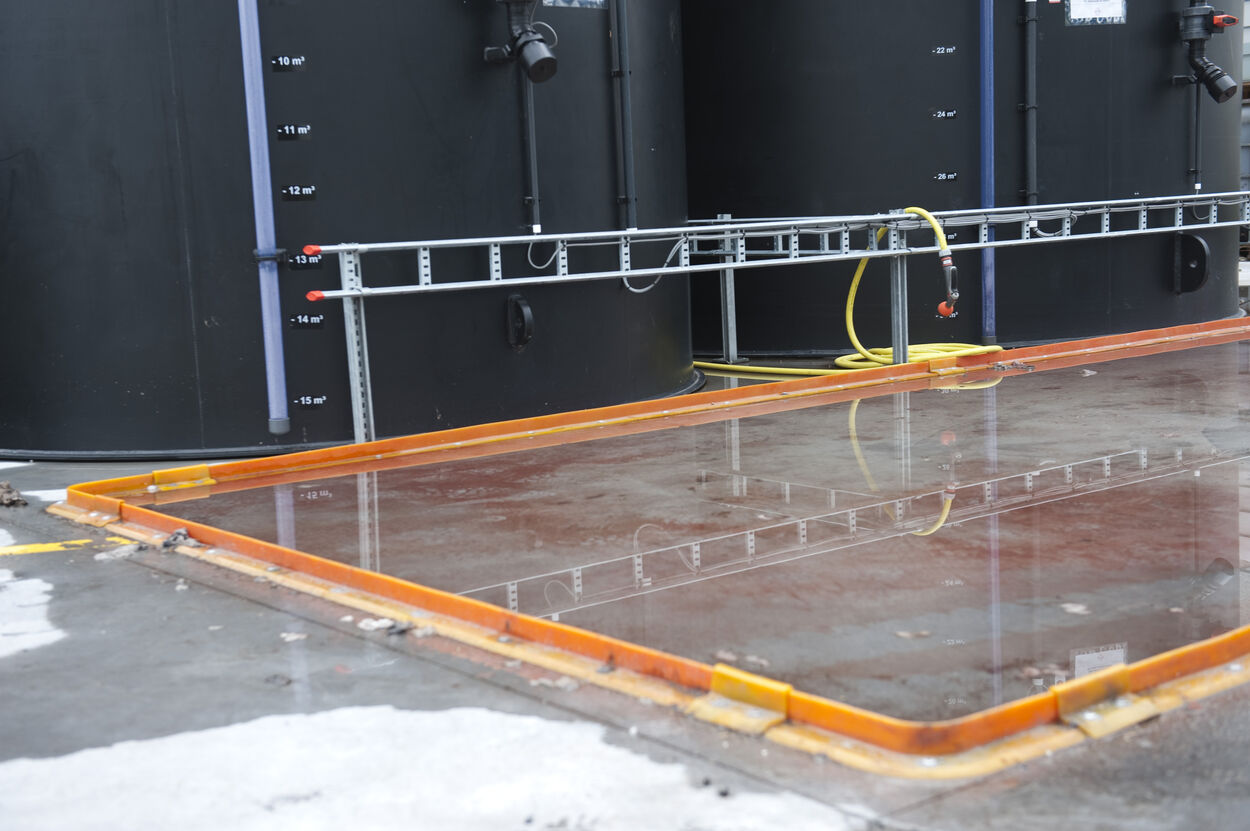

- CGK Group provided via ecobarriers an unloading bay with filling point and discharge pit. When a truck fills the tank, incidents are smoothly contained. Even into the sewage system, thanks to an automatic valve in the discharge pit.

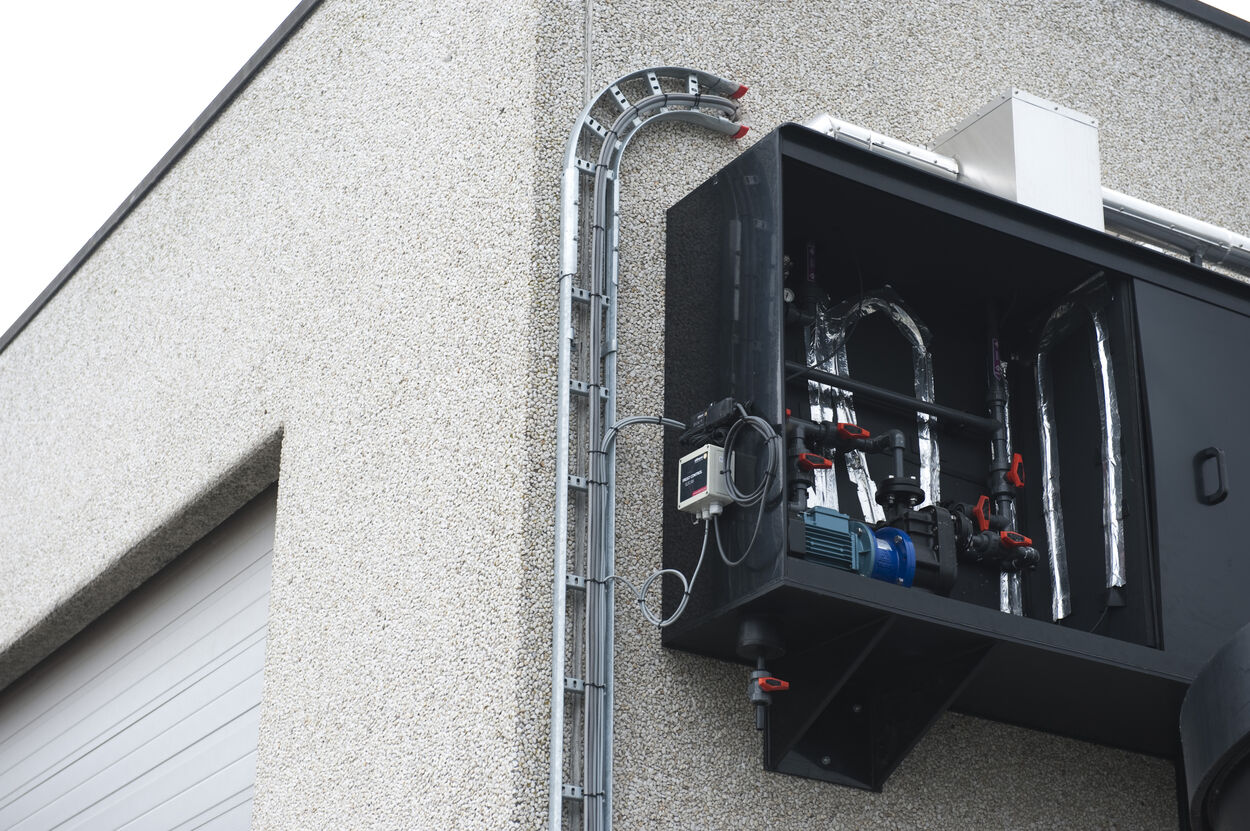

- A pump box and a pack of piping ensure the transport of chemicals. The flow meter guarantees the correct dose, while the 2 self-priming pumps with purge valves prevent siphoning and overpressure. Because hydrogen peroxide degasses easily when pumping, and maintenance work must be done safely.

- To avoid frozen chemicals, the pipes were given insulation. The pump cabinet was conceived with tracing, controlled by a temperature probe.