Water reuse plant (Alpro)

The customer

Alpro is a Belgian food producer specializing in the production of plant-based alternatives to dairy products.

Purpose

Water is an essential part of production at Alpro. Most of the water impact is in growing the ingredients, but large amounts of water are also used for cleaning the factories. To recover and save water , they partnered with De Watergroep and Eurowater for a water reuse plant.

Problem-solution

For the design, construction, operation and maintenance of the plant, Alpro engaged the experts at De Water Group. The construction of the project was supported by Eurowater - who in turn called on CGK Group to install the piping, dosing cabinets, storage tanks and process tanks.

We supervised this project from A to Z: from engineering, production and installation to start-up and fine tuning afterwards.

CGK's task consisted of:

- Supply and installation of 7 double-walledchemical tanks:

- 6 double-walled Astro tanks

- 1 double-walled plate tank made as wide and high as possible to store as much volume as possible. This tank was also fitted with a platform in GRP to ensure good access to the sensors.

- The tanks were transported and moved in under the watchful eye of a CGK employee.

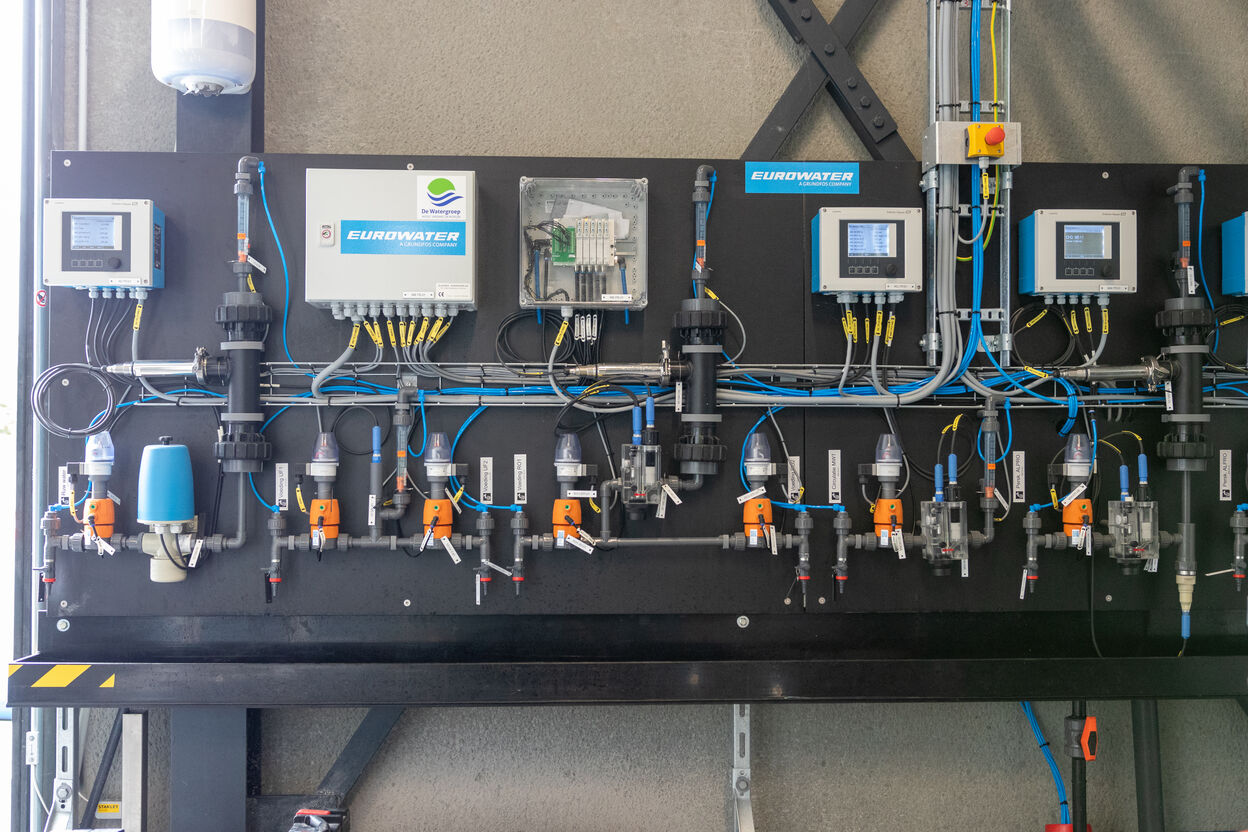

- Delivery and installation of 4 dosing and pumping cabinets:

- All liquids are together in one cabinet and each has its own connection.

- The dosing cabinets have multiple pumps and are equipped with different compartments making it possible to put multiple products in the cabinet without mixing between the liquids.

- The pump cabinets are equipped with leak detection, transparent front panel, drain valve, flush valves and pressure holding valve. These were fully tested by CGK before installation.

- The cabinets are made of PP. This material is available in a lighter color than PE (=black), which makes it more pleasant for employees to work in the cabinets.

- Supply, production and installation of a filling cabinet:

- The filling cabinet was fully customized by CGK with specific filling points and dimensions.

- The front of the filling cabinet has a transparent door panel. To save space, we used a sliding door (moving up and to) instead of opening doors.

- The filling cabinet was constructed so that it can be locked during the filling process. This is to increaseoperator safety in the event of a leak.

- Installation of single-walled and double-walled piping:

- The connecting piping between the different parts of the water treatment was carried out in HDPE piping. The units themselves opted for PVC.

- For the chemical piping we opted for double-walled piping consisting of a transparent PVC pipe as outer pipe and a flexible one as medium pipe. This way, a leak can immediately be visually detected and we protect the installation, the employees and the environment.

- To fully comply with the VLAREM II legislation, we also installed 3 eye showers and body showers inside.