Food-approved isophthalic plastic grating (UTB)

The customer

Unicum Trade Botanicals is an expert in the production of dietary supplements, covering everything from formulation and procurement of raw materials to packaging and transportation.

Purpose

The platform in UTB's new production hall needed to be equipped with isophthalic plastic grating that is fully 'food approved.'

Problem-solution

As part of UTB's capacity expansion, an additional installation was placed in the new production hall. The platform provides production staff with easy and safe access to the mixing tanks for tasks such as inspection and the addition of specific substances.

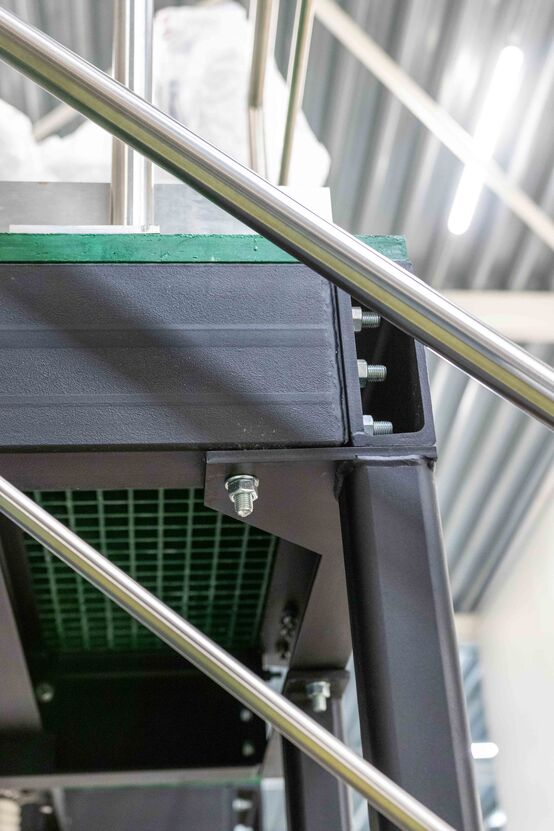

Since food additives are often highly corrosive, the platform was equipped with isophthalic plastic grating (the green panels shown in the photos).

- Given the strict food safety requirements, the grating needed to be fully food-approved. For this purpose, we used a chemically resistant Isophthalic Polyester Resin.

- The grating is extremely strong, capable of supporting the weight of staff.

- Closed grating panels were used, ensuring they fit together seamlessly.

- The panels feature a thin anti-slip layer that remains easy to clean.

- An additional challenge was the precision work required: Based on the plans, the grating panels were pre-cut as much as possible in our workshop. Since they needed to fit together with millimeter precision, further adjustments were made during the on-site installation.

The team that realised this project

Project manager Henri-Tom

Sales Engineer Hughes

Lead technician Wim