Expansion of production line (food industry)

The customer

A large Limburg-based packaging producer for the food industry.

Purpose

Answering the growing demand with a new production line.

Problem-solution

- After evaluating the conditions and their precise application, CGK Group came up with a sparkling new design. The material conditions? Resistant to chemical vapors & liquids, resistant to temperatures from 18 to 38°C, fire retardant, high mechanical strength and long life.

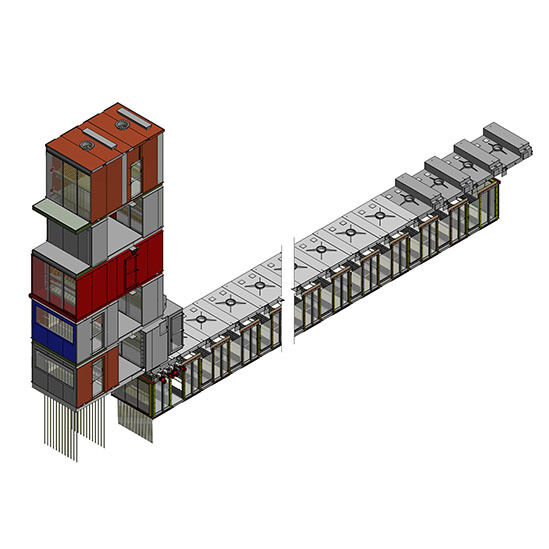

- The installation conditions? Large and transparent access doors, no escaping vapors and liquids, no gas or liquid accumulations and quasi complete airtightness. A narrow passage to the new production line played an additional major role. The plant was therefore designed modularly, with many prepared modules and elements. This resulted in considerable time and therefore budget savings, thanks to the convenient click system during installation.

- High quality was high in the specifications. Because the machines work 7 days a week and production was only allowed to stop for two years. CGK Group opted for a 19 m high extrusion tower with plastics (including twin-wall panels in PPS) and GRP structures and gratings.