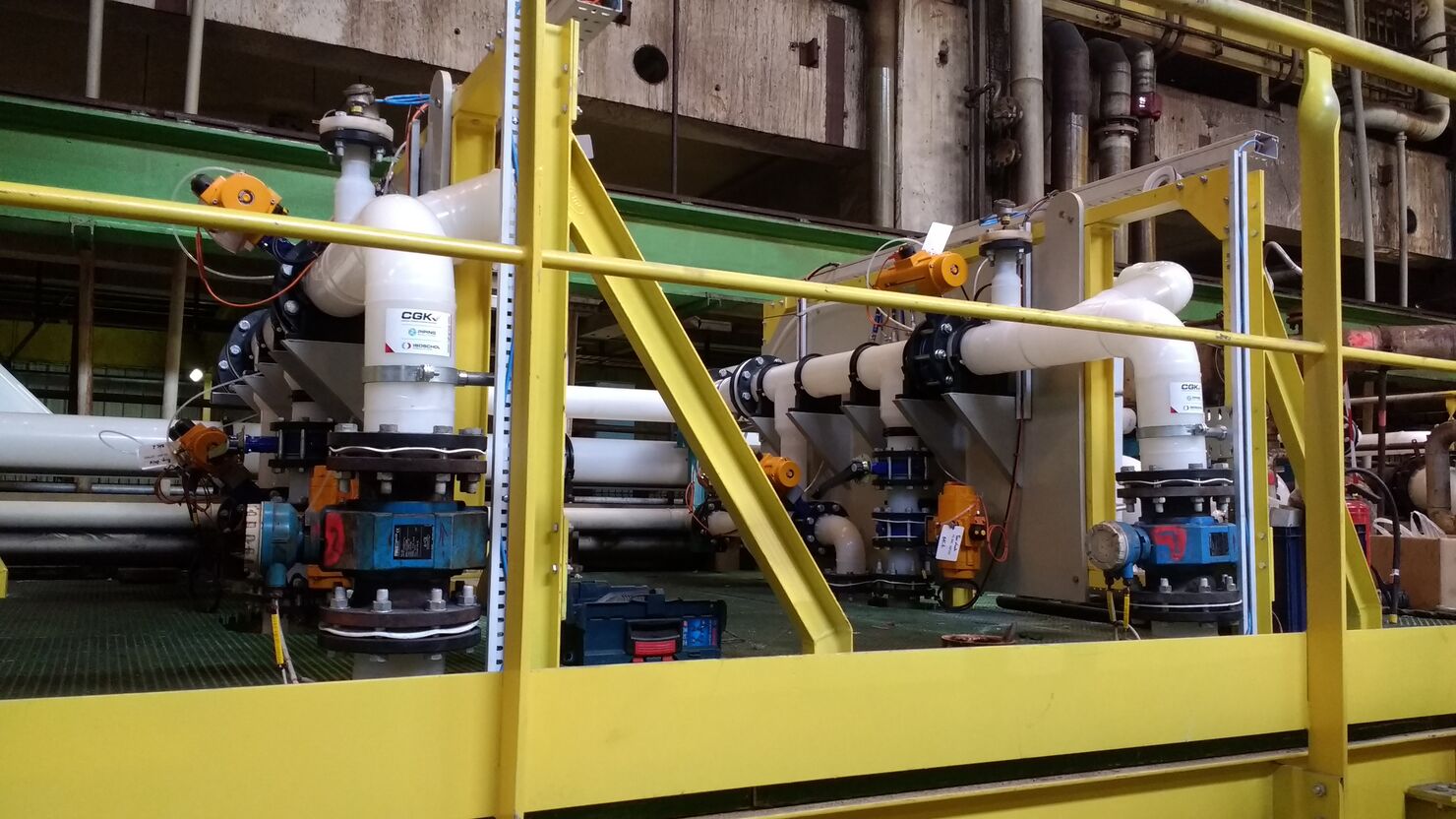

Assembly of pipework (Aperam)

The customer

Aperam is a major stainless steel producer with plants in northern France and elsewhere.

Purpose

Assembly of piping in PVDF.

Problem-solution

Problem

The old piping had seen its best days, but the new piping also had to bring a mix of HCl and H2O2, with a temperature of 75°C, to the process baths. The biggest challenge was the deadline: in 2 weeks, all pipes had to be dismantled and replaced. Summer weeks, moreover, because of the summer shutdown.

Solution

- CGK Group prepared the job meticulously, thanks to a 3D scan. This allowed our engineering department to optimally measure the piping route and have the pipes installed in the right place. Result? No assembly problems, because the new pipes were adapted to the existing situation. The close cooperation with Aperam ensured an efficient arrangement of the valves.

- CGK Group welded different assemblies, mainly PVDF piping with 250 mm diameter and pressure class PN16. Everything was prepared in the workshop, so that assembly went extra smoothly. The panels with valves were assembled just as easily at Aperam, while the pipes came on the existing support.

- CGK Group renewed the platform at the same time.