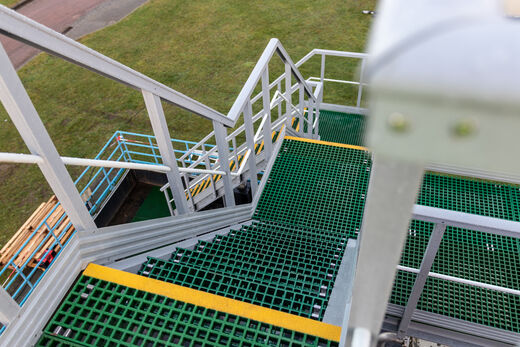

How do I choose the right GRP grating?

Our plastic gratings vary based on the type of resin used in their manufacture, the non-slip coating applied to their surface, and their dimensions.

1. Resin type

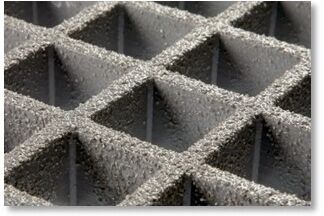

Our plastic grids are created by placing glass fibre bundles in a waffle-shaped mould and adding resin. This creates a grating with square mesh openings. GRP gratings are available in several standard resin types for specific applications:

Plastic gratings for general use (infrastructure)

Resin type: orthophthalic polyester

- Standard colour: light grey ±RAL7035

- Limited fire resistance

- Maximum temperature: 100°C

Plastic gratings for chemicals

Resin type: isophthalic polyester

- Standard colour: green ±RAL6002

- Good fire resistance with limited smoke formation

- Maximum temperature: 105°C

Plastic grids for highly corrosive substances

Resin type: vinylester resin

- Standard colour: red ±RAL3000

- Good fire resistance with limited smoke formation

- Maximum temperature: 110°C

2. Anti-slip

Our walking grids are completed with a specific type of anti-slip coating tailored to the application.

3. Grid dimensions

The grating dimensions (surface area, mesh size and height) depend mainly on the required distributed load per m² or point load and this in combination with the free span.

Standard EN ISO 14122-2 prescribes a maximum deflection of 1/200 counted from the free span. For GRP gratings, a deflection of 1/100 with respect to the free span is often applied.

Want to know more about GRP gratings?

Leave your details or request a no-obligation quote.