Jet cleaner with rotating delivery pipe

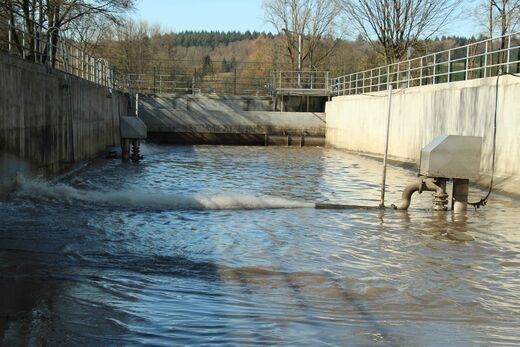

Avoid sludge, nasty odours and rot in wastewater basins with our jet cleaners. Thanks to this high-pressure cleaner, you easily manage to completely empty your water basins without leaving any filth residues behind.

This swing jet cleaner is specially designed for automatic cleaning and power generation in basins. The cleaner is fully submersible, contains a pebble filter and has a hinged, gas-tight stainless steel lid.

Powerful flow for optimal cleaning

Swing jet cleaners operate on the principle of a water jet pump.

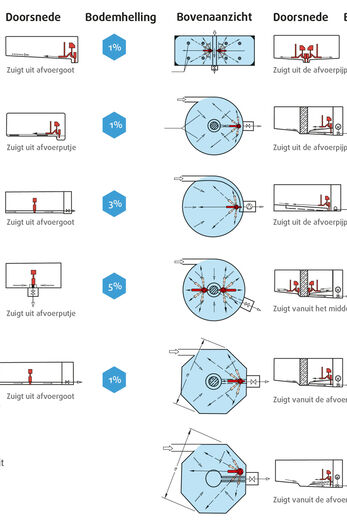

The pump is set up both inside and outside the basin and sucks water from the lowest point of the basin. Additional air is added to this suctioned water via a vertical tube. Together, this water with air is blown horizontally out of the nozzle at high speed. This creates a flow in the basin that keeps the suspended matter moving. As a result, the suspended matter does not reach the bottom of the basin.

When the basin is pumped empty, for example towards the water treatment plant, the suspended solids are discharged along with it.

Jet cleaner process

1. During filling

At the moment the basin is filled, the swing jet cleaner is at rest.2. When emptying

Does the water basin level not rise further? Then the cleaner will take effect.

The cleaner aerates the basin at a fixed interval. The nozzle first points in one direction and then starts rotating. The nozzle stops for a certain time at defined stop points. The contents of the basin are thus thoroughly mixed.

3. Final cleaning

At a minimum water level (e.g. 1 metre) in the basin, final cleaning begins. Suspended material is also removed from the basin during this phase.

Unique properties

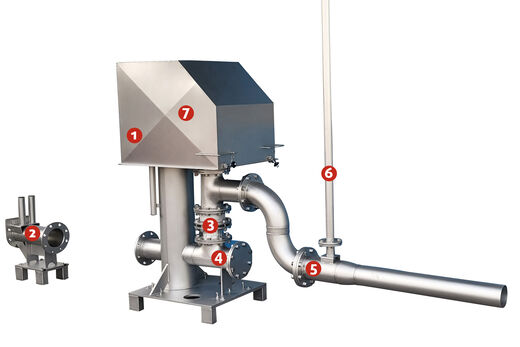

Gas-tight stainless steel cover - foldable

The swing jet cleaner has a special design that ensures an air bubble is formed in the housing. This allows the cleaner to be fully submerged without the motor coming into contact with liquids and consequently also remains protected from filth. This means that the cleaner can be used reliably and for long periods without much maintenance.

Pump base 180°

The pump base can be mounted on a flange or offset. The pump base is also manufacturer-independent.

Stainless steel swivel joint

The stainless steel swivel has a flange and insulation and can be adjusted manually. It has special Teflon sealing gaskets that ensure safe and durable rotary movements during the process.

Pebble filter

This filters out stones and filth before it gets to the injector, preventing it from clogging up. It also aids in reducing the wear on components that conduct electricity.

Jet nozzle rotation range up to 280°

The device offers a swivel range of up to 280°, utilizing adjustable limit switches. It can be operated with a 4-20 mA/O-10 V signal, which provides feedback on the position.

Air intake pipe

Additional air is supplied to the water via the vertical air intake tube. This prevents unpleasant odours and rotting.

Motor

Internally installed high-quality rotary motor with EX approval according to ATEX 1087.

Dimensions

Need a jet cleaner with rotating delivery tube?

Get more information or request a no-obligation quote.