Silos for powders and granulates

Are you looking for a silo that completely empties without leaving any residue? Our rotationally moulded conical tanks made of MDPE or linear polyethylene are perfectly suited for the storage, processing, and dosing of powders and granulates (such as sugar, flour, cocoa powder, milk powder, grain, or feed).

Thanks to the conical bottom, the tank fully drains, preventing valuable material from being left behind.

Why choose a silo from CGK?

- Complete drainage without residue

- Durable and cost-effective

- Available in various volumes (from 330 litres)

- Mirror-smooth tank walls for optimal product flow

- Lightweight and easy to handle

- Certified for food safety (FDA-certified)

- UV-resistant and built to withstand external conditions

- Constructed according to the strictest building codes

- Fast delivery and available in custom designs

Accessories

Our silos can be equipped with a variety of accessories tailored to your specific application.

Drainage options

- Outlet diameters of 200 mm, 350 mm, or 450 mm

- For smaller tanks: from 2”

- Guillotine valve, butterfly valve, or diaphragm valve (in aluminium or stainless steel)

Customisable frames

- Available in painted, galvanised, or stainless steel

- U-profile base for easy lifting and moving with a forklift

- Elevated frames available (to raise the tank up to 1800 mm)

- Options with fixed or swivel wheels for added mobility

- Stackable versions for efficient storage

Additional closures and ventilation

- Removable screw lid with ventilation opening

Wall thickness

- Adjustable depending on the powder’s density

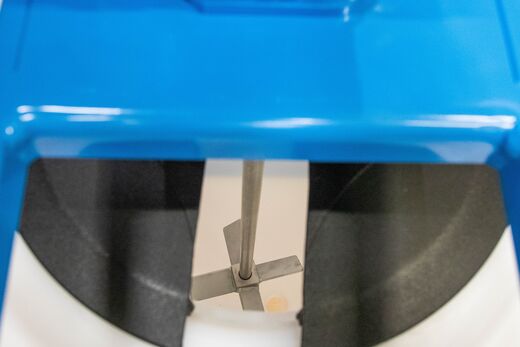

Agitator

For products that tend to clump quickly or require constant mixing, an agitator can be added. This is ideal for the food industry (e.g. flour or sugar blends), but also for chemical applications where solids need to remain homogeneously mixed.

Do you have specific requirements?

Customisation is possible to ensure the silo fits perfectly into your production process.

Take a look at our tailor-made storage, mixing, and process tanks to find the ideal solution for your needs.

Need a storage tank for powder or granules?

Get more information or request a no-obligation quotation.

Advantages of Conical Tanks

- Complete drainage – Thanks to the conical bottom, powders and granulates flow out of the tank completely, preventing product build-up and waste.

- Less residue – Ideal for sectors where thorough cleaning is essential, such as the food and pharmaceutical industries.

- Efficient dosing – Suitable for accurate and controlled feeding of powders and granulates in production processes.

- Versatile applications – Usable across various industries, including food, chemical, plastics, and agriculture.

Applications

Food industry

In the food industry, silos are used for the storage and processing of dry ingredients such as:

- Sugar, flour, cocoa, and milk powder

- Nutritional supplements like protein powders and spice blends

Why choose a silo?

- Prevents product build-up and ensures fast, residue-free emptying

- Suitable for mixing processes such as the production of sauces, dressings, chocolate, and dairy products

- Efficient in fermentation processes (beer, wine, yogurt)

Chemical sector

The chemical sector uses silos for the storage and processing of:

- Bulk storage of pharmaceutical powders and ingredients

- Chemical powders such as fertilizers, pigments, and polymers (PE, PP, PVC)

Why choose a silo?

- Prevents residue when handling corrosive substances

- Enables controlled chemical reactions and emulsion formation

- Suitable for use as reactor vessels and in mixing processes

Plastic industry

In the plastics industry, silos are used for storing plastic granulates such as:

- Plastic granules

- PVC and PET granules

- Polypropylene pellets

Why choose a silo?

- Efficient storage and transport of granulates for injection moulding and extrusion processes

- Prevents clumping and material build-up

Agricultural sector

Silos are indispensable in the agricultural sector for:

- Storing animal feed such as grain, corn, soy, and compound feed

- Fertilizer storage and dosing

- Water storage and agricultural additives

Why choose a silo?

- Ensures fast discharge of feed and pellets

- Suitable for efficient production of compound feed

Request a quote

Contact Daan Devlaminck

Design & Project Engineer