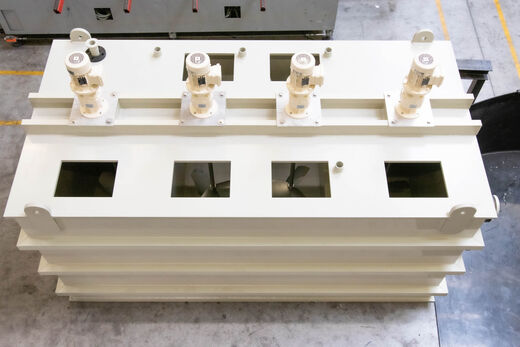

Customised process and mixing tanks

In a process or mixing tank, liquids are 'treated' in various ways: mixing, diluting, neutralising, flocculating, emulsifying ... Process/mixing tanks are mainly used in water treatment and chemistry.

An adapted agitator ensures that no sediment or sludge forms at the bottom. To avoid unwanted chemical reactions, we carefully select the right agitator or it can be lined with PP. With anti-vortex plates, we prevent the liquid from entering a swirl.

CGK Group custom-builds your process or mixing tank. For example, we also offer decanters or can fit your tank with a sloping bottom to allow it to be completely emptied.

Advantages of our process and mixing tanks

Our tanks are built for the long term and are also very cost-effective.

A few more advantages:- careful choice of materials (HDPE, PP, PVDF, etc.)

- cylindrical vessels

- variable colour and wall thickness

- impact and shock-resistant

- UV-resistant

- antistatic

- food grade

- colourfast

Standard production ensures fast delivery..

No idea what to do with your old process tank? CGK Group removes and transports the old tank and installs the new one, pipework included if necessary.

Need a (new) process or mixing tank?

Get more information or request a no-obligation quotation.