Skid for new water treatment process (Solvay)

The customer

Belgian chemical giant Solvay manufactures plastics, among other things.

Purpose

Designing and building a pilot skid.

Problem-solution

Problem

Solvay wanted to prototype a skid to test the effectiveness of a new process in water treatment (and then place it with a variety of customers).

Solution

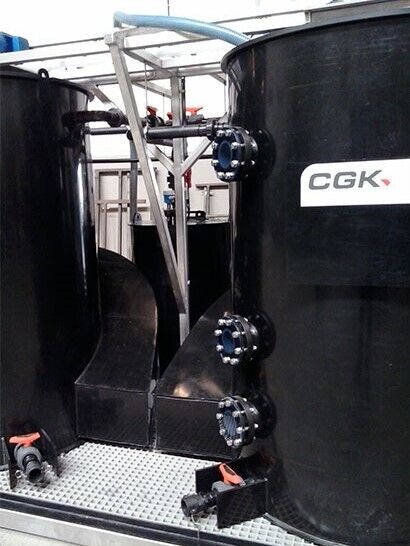

- CGK Group and the Solvay team fitted a stainless steel chassis with a drip tray and a polyester grid. On the drip tray are 5 plastic tanks, 2 of which have sloping bottoms and 1 with conical bottoms. In addition, 3 agitators were installed.

- All PE tanks are connected via HDPE pipes, while 4 pumps send the water to be treated through the system. Sensors monitor the tank volume, electrical cabling and a Siemens PLC control complete the picture.

- Timing proved to be the big challenge: CGK Group delivered the project in 3 months. From 3D design to customer testing in our workshops. The 2.5 meter skid width also meant that no special transport permits were required.